END-TO-END PROVIDER

For over 40 years, Brentwood’s passion has been helping customers turn ideas into reality through innovative thermoforming and injection molding services. Brentwood works closely with our customers to develop and execute the best design, materials, and manufacturing strategy for products of all shapes and sizes. This comprehensive approach includes skilled design engineering and support all the way through prototyping, tool design, and fulfillment. After your product has met our stringent manufacturing and quality requirements, Brentwood’s customer service team coordinates on-time deliveries and future reorders.

Light Gauge Thermoforming

Brentwood produces light gauge thermoformed plastic packaging and components for the medical, dental, shipping, battery, and other manufacturing industries. Our solutions range from medical device enclosures to protective and display packaging, optimized for usability, appearance, and durability.

- Ideal for consumer and medical packaging applications

- State-of-the-art equipment, including a Class 7 Clean Room

- Wide variety of materials, thicknesses, and lengths available

- High-speed inline equipment to meet high-volume and fast delivery requirements

- In-house design & engineering expertise

- High-speed inline equipment

- Secondary operations for full part assembly

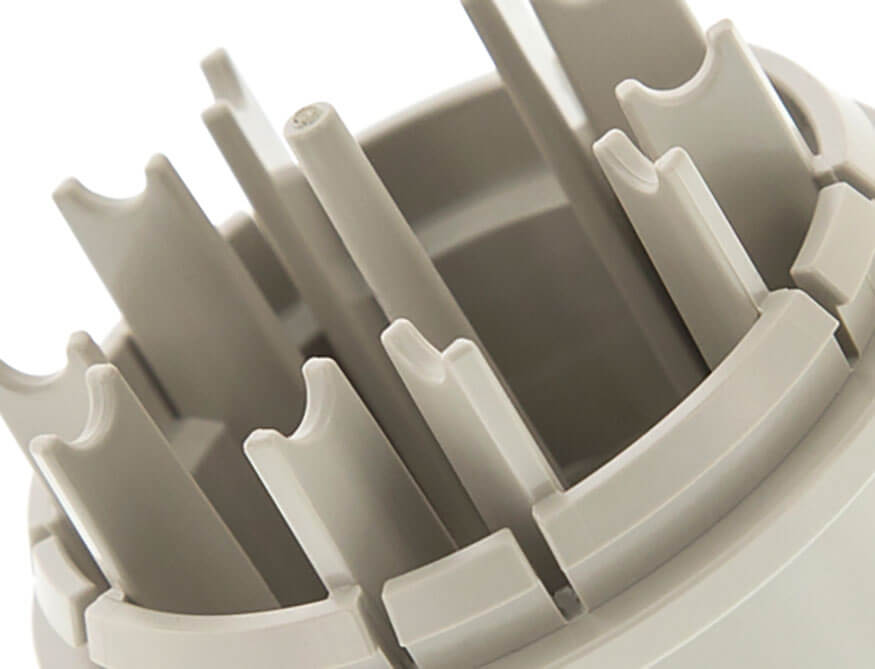

Heavy Gauge Thermoforming

Brentwood produces heavy gauge thermoformed structural and decorative components for the transportation, consumer, agriculture, medical, aircraft, and other manufacturing industries. Our solutions range from detailed interior trim pieces to rigid exterior panels, optimized for durability, appearance, and uniformity to provide alternatives to heavy sheet metal.

- Extensive experience producing components for a range of industries

- Wide variety of materials, thicknesses, and lengths available

- Able to form parts with intricate surface details, textures, and finishes

- Company strength allows us to support long development cycles

- In-house design & engineering expertise

- High-speed inline equipment

- Secondary operations for full part assembly