Learning Center

Learning Articles

Jun 28

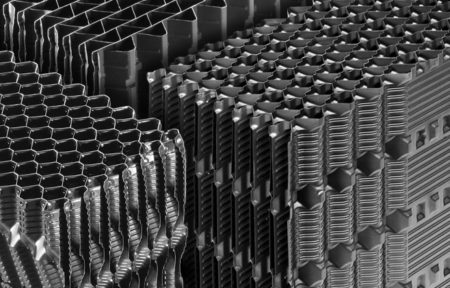

Cooling Tower Counterflow Fill Media Review

It’s important to regularly touch base on the basics of cooling towers to provide anyone new to the industry with vital information, but it’s also a good reminder for those who have been in the industry for many years. There are… Read More

Jan 29

How Nozzles Work Within a Cooling Tower System

Why Are Nozzles Important? Everyone knows how important the fill is to a cooling tower’s performance. Since fill is the heat transfer medium around which the “box” that is the cooling tower is built, you could argue that it’s the… Read More

Nov 19

Choosing the Right Fill for Your Tower & Application

A question we often receive is, “How can you be certain that a particular fill will work in my tower?” Well, first, we take a stack of cards and write one fill model on each card. Then, we go… Read More

Oct 01

Cooling Tower Drift vs. Splashout

Drift can be defined as the water that is emitted along with the exhaust air of a cooling tower. The drift droplets that escape contain the same chemical, bacterial, and particulate matter of the circulating water from which they… Read More

Sep 24

FM Certification Questions Answered

We received a comment on our first FM Approvals blog post and decided to dedicate another post to the answer. You can check out the original article and comment here. In a nutshell, the user commented that FM certification is… Read More

Sep 02

How do you minimize Legionella bacteria contamination?

Since Legionella bacteria are present in almost every ground and surface water, it should be noted that the vast majority of cooling towers will have some level of the bacteria in their circulating water. The issue then becomes how best… Read More

Jul 29

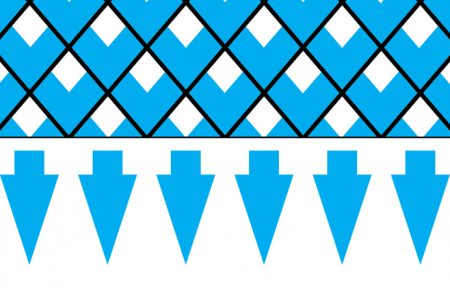

Cross-stacking Improves Cooling Tower Water Distribution

We recently had a question about the installation scheme of our cross-fluted fill in a tower with 3 feet of fill depth. When installing 1-foot-deep layers, or any more than layer, of fill we highly recommend that each layer… Read More

Jul 21

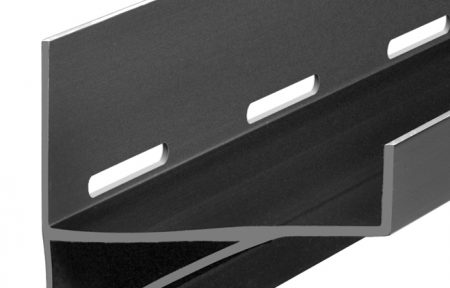

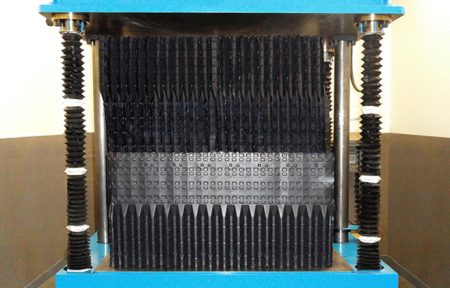

Crossflow Drift Eliminator Supports

Brentwood produces several drift eliminator supports for crossflow cooling tower applications which require non-integral drift eliminators, such as XF150MAx and XF80MAx. The drift eliminator supports offered include XF600, top/bottom profile, intermediate profile, and XF column-mounts. How do you apply each of… Read More

Jun 16

“Buy American” Cooling Tower Products

Do Brentwood products meet “Buy American” requirements? Yes, all of Brentwood’s cooling tower products sold in the U.S. are made in America and utilize American-sourced materials. Being a second generation family-owned company, Brentwood is dedicated to supporting the local economies of… Read More

Jun 11

What does “drift rate” mean?

For cooling tower products and applications, the industry defines the effectiveness of a drift eliminator product in terms of its drift rate. This rating is usually presented in the form of a percentage. You may ask, “Percentage of what?”… Percentage… Read More

May 14

Brentwood Cooling Tower: Service for All

I am just starting up my business and am not a large company yet, can I work directly with Brentwood? The answer is…absolutely! Yes, Brentwood is a global company, but we take pride in the fact that we are large… Read More

May 05

What factors into cooling tower pack strength?

One of the first factors to consider is how the packs are put together: glued vs. mechanically assembled (MA). In a nutshell, the strength requirements for the majority of standard applications in a cooling tower can be satisfied by both… Read More