Learning Center

Learning Articles

Oct 03

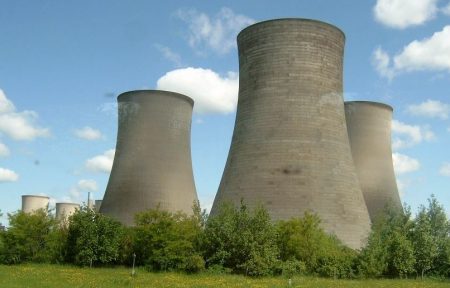

Cooling Tower Water Treatment Recommendations

Brentwood knows that there’s more to your cooling tower than the fill and drift eliminators we supply. In fact, the primary maintenance task for cooling towers revolves around water treatment. Unfortunately, there is no “one size fits all” water treatment… Read More

Sep 05

Fill Fouling & The Effect On Tower Performance

Just what are the effects of fouling on a fill, and what does it mean for overall tower performance? This is a question that Brentwood has been researching for a few years. As film fills have evolved and tower owner/operators… Read More

Jul 10

Does flute geometry and the mode of heat transfer (trickle vs. splash) affect fouling resistance in “wire-frame” cooling tower fills?

At the recently concluded 2017 CTI Annual Conference in New Orleans, Brentwood’s own Angela Zaorski and Bill Miller presented a paper regarding their research into this topic. The purpose of the research was to verify whether the “wire-frame” fills being introduced to… Read More

Jun 14

Cooling Tower Fill: Hanging Sheets vs. Fill Blocks

We continuously receive calls from cooling tower owners describing the following: “I have a metal crossflow tower that has been operating for a few years now, and there are a lot of water droplets coming out of the top of… Read More

May 16

How Cooling Tower Drift Relates to PM10 and PM2.5 Emissions

A topic that is attracting more and more attention in the cooling tower industry is PM10 and PM2.5 emissions. Reduced emissions to the environment are being required as governmental permitting regulations continue to get tighter. From a cooling tower perspective,… Read More

Apr 24

CFUltra: Leading the Cooling Tower Industry to Reduced Drift Levels

Welcome to our first vlog (video blog)! In this 2-minute video, you’ll get a quick education about how Brentwood’s all-new CFUltra counterflow drift eliminator was developed and the performance it provides: Video transcription: Building off the already industry-leading CF80MAx product,… Read More

Mar 02

How much difference can upgrading my drift eliminators make?

That’s a good, and common, question. To answer it, we can run an example calculation, making a few assumptions: We will design our analysis around a counterflow, induced draft cooling tower utilizing blade-style eliminators. We will assume the water quality… Read More

Jan 03

Why might an owner not choose the highest efficiency fill for his tower repack?

This question is one we walk through on a regular basis with many of our customers. We also perform a lot of thermal runs using our STAR program to model towers and compare the benefits of using a cross-fluted fill… Read More

Dec 08

The Benefits of Reducing Splashout

Splashout is one of those small issues with a tower that we always plan to fix, but it has a tendency to fall to the bottom of the priority list. However, with summer coming to an end and fall work… Read More

Nov 03

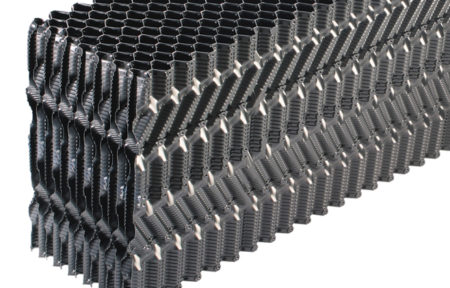

Fill Fouling Fundamentals

Fill fouling is the deposition of material on the fill’s heat transfer surfaces. It involves one or more of the following processes: 1) biological fouling due to biofilm development, 2) deposition of suspended solids due to sedimentation, 3) scaling of… Read More

Aug 16

The Importance of Material Property Standards for Cooling Tower Fill

All PVC is not equal. Therefore, it should meet specific material property standards that are set by Cooling Technology Institute and can be found in (CTI) STD-136. The importance of CTI STD-136 is to set a minimum threshold for… Read More

Aug 03

Thermoforming Process: Before- vs. After-Forming Thickness of PVC

When purchasing film fills, it is important to understand the difference between before-forming and after-forming thickness as well as the quality of PVC being formed. During the thermoforming process, the PVC sheet is warmed in an oven and then stretched… Read More