Learning Center

Learning Articles

Feb 12

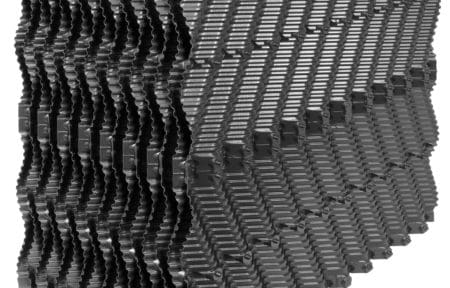

Splash Fill Innovation

Splash fills have been used in cooling towers for almost as long as cooling towers have existed. The original splash fill designs of simple wood slats hung in a gridwork system, or platforms made of wood slats, eventually shifted toward… Read More

Oct 02

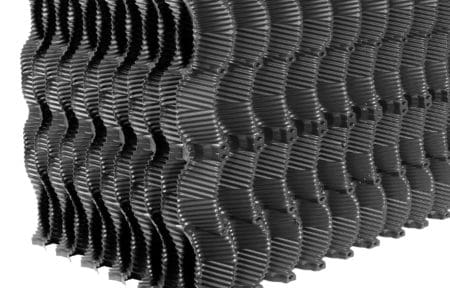

How ThermaCross Boosts Performance

In today’s cooling tower market, tower owners and operators are trying to get the most capacity out of their existing assets. There are many 19mm cross-fluted fills available in the market, and there are wide variations in those product designs… Read More

Sep 06

ShockWave Fill Designed For Use In Petrochem Applications

The petroleum refinery process is both interesting and complex, combining numerous chemical processes to produce an array of products. Cooling systems play an integral part in the production of these products. Unlike other applications, such as electrical generation or HVAC… Read More

Aug 19

Choosing The Right Fill Based On Water Quality

Brentwood often gets emails for a situation that goes something like, “Here is a report showing the water for my cooling tower. What fill should I use?” That’s a good question to ask, although answering it at times can be a… Read More

Apr 02

What Does 1 Degree Colder Water Mean To You?

When most people think of temperature, like the temperature outside for instance, a 1˚ difference doesn’t have much of an effect. But when we’re discussing the cooling process, as you may know, it can make a world of difference! By… Read More

Mar 11

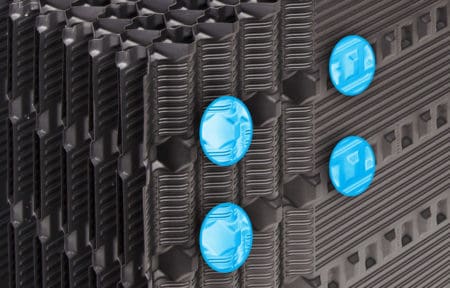

How Brentwood’s ShockWave Fill Provides a Better Balance of Efficiency & Fouling Resistance

The new ShockWave™ 25 fill’s enhanced vertical-flute design helps to narrow the typical compromise that choice of fill typically entails: cooling performance vs. fouling resistance. For years, the premise has been that in order to have a fill that resists fouling,… Read More

Dec 06

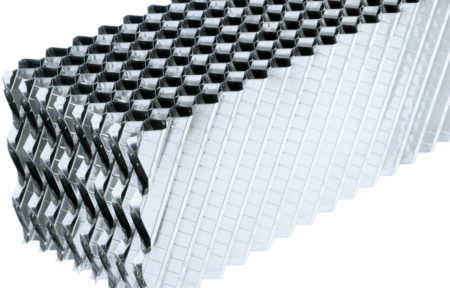

When To Use A Stainless Steel Fill

Brentwood’s ability to manufacture a wide range of products for our customers is not necessarily limited to our ability to do so in plastics. Some customers are actually seeing an increase in the need for fill products made from other… Read More

Oct 16

How Drift Can Affect Your Process & Components

When referencing the detrimental effects of cooling tower drift, we often discuss emissions levels, lost water, and the cost of treating the water that’s escaping the tower. Another item worth considering is the effect that drift has on the performance… Read More

Mar 20

D15PERF For Turbine Inlet Applications

Some Brentwood products are specifically designed for a single application. One such product is the D15PERF. The D15PERF was designed intentionally for the turbine inlet market and incorporates a number of features that make it well-suited for this critical application.… Read More

Jan 23

What We Really Mean When We Reference “Glued” Film Fill Packs

There are many different words to describe the agent used to bond two objects together: glue, adhesive, cement, and solvent cements. Of these, one sticks out as the simplest ─ glue. However, the definitions of the four terms vary: Glue:… Read More

Dec 11

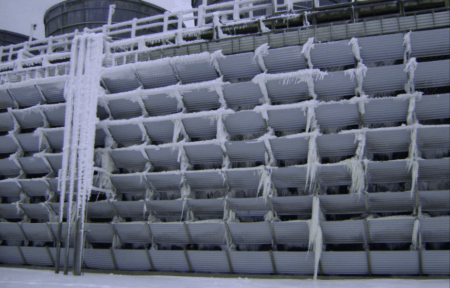

Water Management and Winter Operation of Cooling Towers

When dealing with a cooling tower one of the main focus points is proper water management. Let’s face it: You have a cooling tower because you have a heat load that needs to be dissipated, and your cooling tower is the… Read More

Nov 01

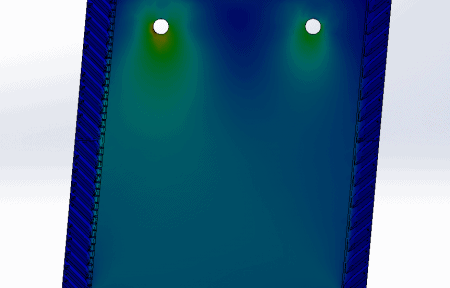

Stresses on Hanging Sheets vs. Bottom-Supported Packs

Figure 1: Stress on hanging sheets As we continue to develop new products, like the XF75Pro, and assist customers all over the world with application questions, it becomes important not just to help with understanding how our products work but… Read More