Diagnostic Housing Equipment for Healthcare

Diagnostic Housing Component

Diagnostic Housing Component

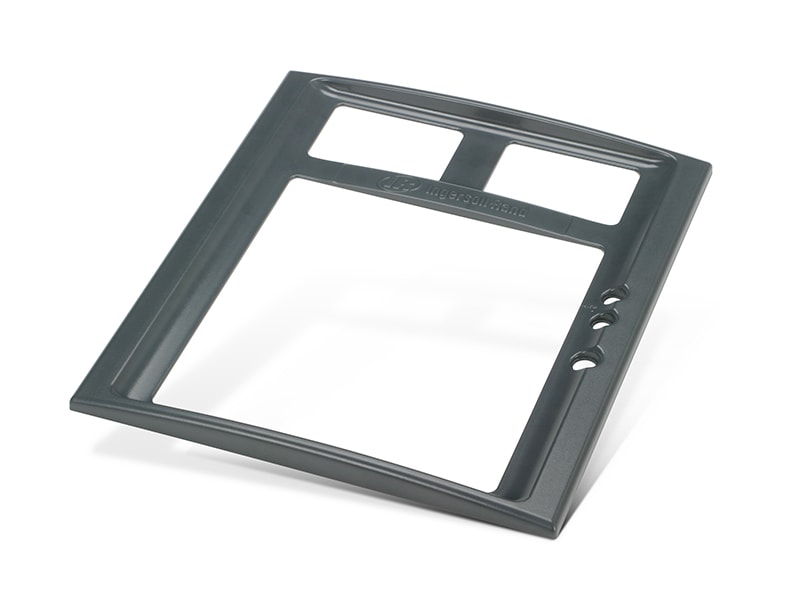

Diagnostic Housing Fascia

Dental Imaging Machine

Heavy Gauge Handling Tray

Services

Part Design

Brentwood collaborates with each customer to develop the right packaging solution for your unique needs. Our team of skilled designers, tool engineers, and CNC programmers works to ensure that the custom-tailored design meets your requirements for performance, functionality, and product protection.

Process Design

Our internal project management team is well-practiced at working with complex timelines and deadlines designed to get your product to market. We ensure the process flows smoothly from the first tooling order through final delivery. After that, project management works directly with our customer service team to make sure you can easily reorder parts.

Tooling

After collaborating with you throughout the design, prototyping, and approval processes, we utilize the knowledge gained to develop high-quality production tooling. All production tooling is produced using top quality materials and is precision machined to the highest tolerances. Post-production, all tools are carefully stored and maintained for future runs.

Quality Planning

Brentwood’s quality management system is integrated into every step of the development process, guaranteeing consistent products that meet or exceed your expectations. With the end user in mind, we continue to innovate in research and design, providing efficient packaging that simplifies handling and reduces material use.

Materials