Medical

Custom medical device packaging and components

for manufacturers that demand precision, innovation,

and reliability from a full-service partner.

Visit Medical

Endless Possibilities

End-to-End Solutions

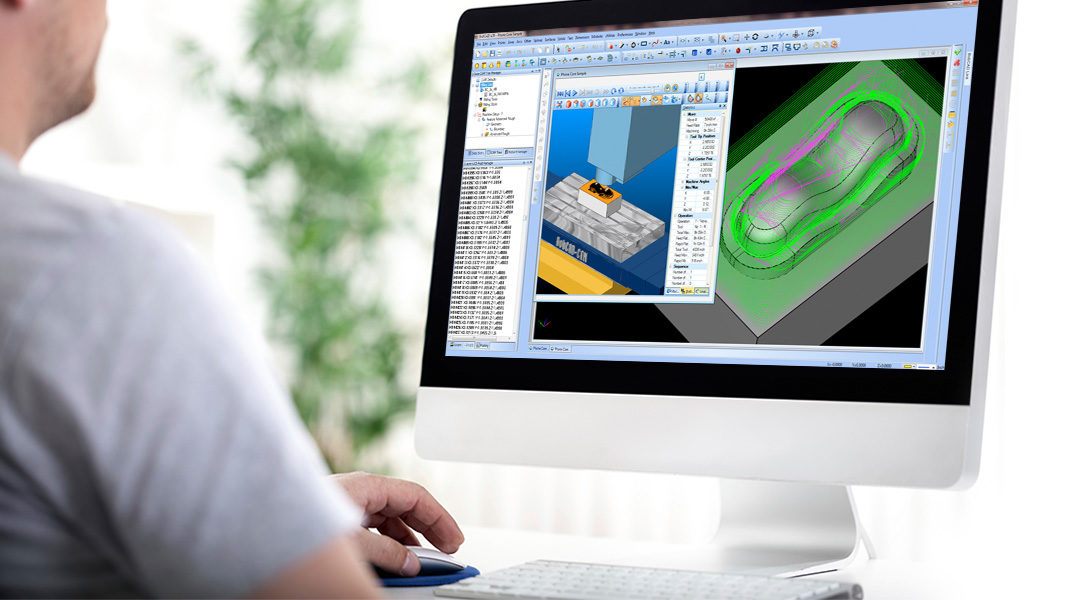

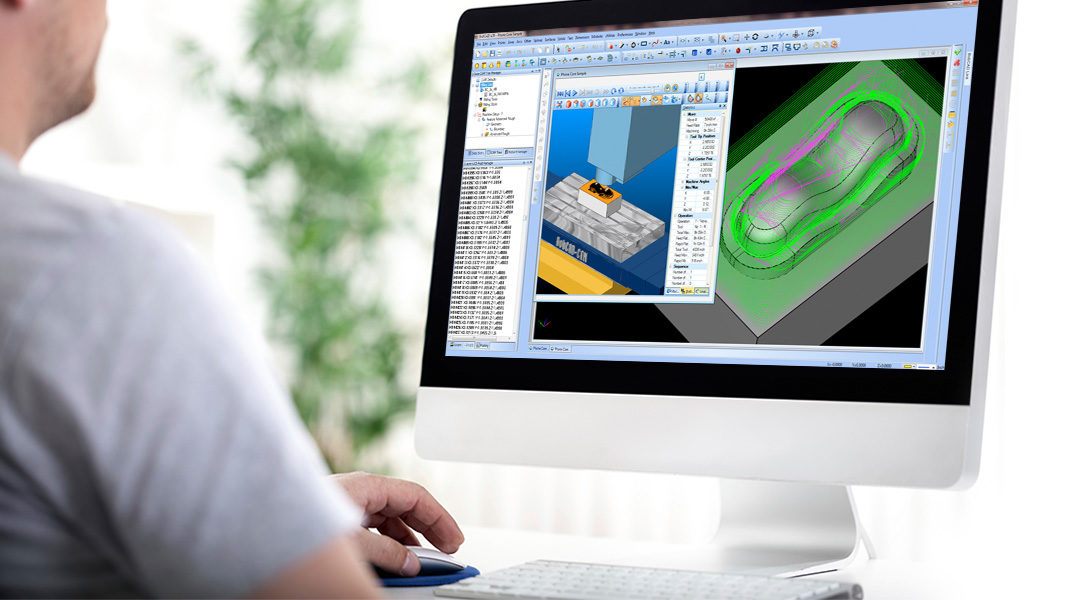

Brentwood is proud to be a full solution provider, working hand-in-hand with you through each project stage from concept to the validated product. We begin by collaborating with you on initial product design and then utilize our rapid prototyping process to turn around samples in days instead of weeks. These prototypes are used to conduct product testing prior to manufacturing production tooling.

Molding Capabilities

Our knowledge of forming techniques, combined with experience using a wide range of materials, allows us to tailor solutions to meet each customer’s requirements for performance and functionality. In addition to our inline and sheet-fed thermoforming capabilities, Brentwood also offers injection molding, overmolding, and secondary assembly services.

Cost-Effective Production

Brentwood’s clean room is equipped with the latest technology available, including automated conveyors, stackers, and robots, which allow us to increase speed to market and handle high-volume runs.

Who We Help

Brentwood is a high-performance partner who innovates precise solutions for even the most demanding medical and dental packaging and device applications. We help:

- Medical, Dental, and Pharmaceutical Companies

- Packaging Designers and Engineers

- Co-Packers and Contract Packaging Companies

Products & Solutions

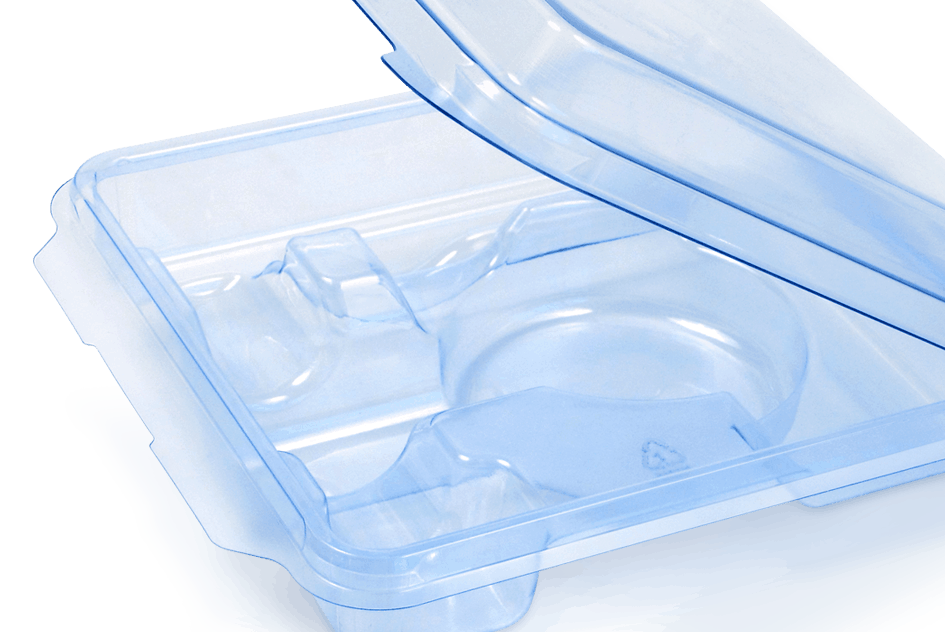

Thermoformed Packaging

Forty years of experience in medical packaging and an even longer history of thermoplastics processing has made Brentwood’s team experts when it comes to choosing the right process and material to get your product to market.

Learn More

Packaging Specialties

Brentwood has developed a number of packaging specialties, including the ability to form long trays up to 72” long and deep tubs up to an 8” depth. Our process expertise enables us to create new design possibilities and also participate in clinical trials.

Learn More

Injection Molded Components

With a dedicated Class 7 injection molding cleanroom, Brentwood is capable of producing high-precision parts with tight tolerances. We also provide in-house design, prototyping, and testing, partnering with our customers through each stage in the development process.

Learn More

Diagnostic Equipment Enclosures

In addition to packaging and injection molding capabilities, Brentwood is able to manufacture complex heavy-gauge parts with intricate surface features. These can be produced cost-effectively for runs of any quantity.

Learn MoreStart a conversation with Brentwood.