CF1200 Overview

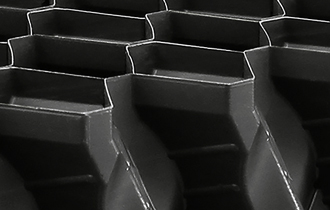

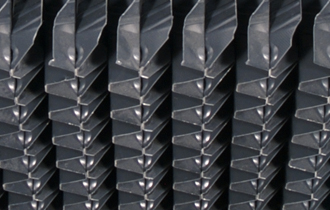

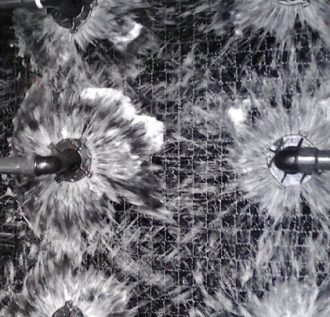

CF1200 has been designed for use in factory-assembled counterflow towers in HVAC and light industrial applications. It can also be used as a distribution pad in 3.9” (100 mm) and 5.9” (150 mm) depths where the water contains very low levels of total suspended solids. CF1200 splits the water stream ten times in an 11.8-inch (300 mm) vertical path, balancing high thermal performance and low pressure drop.

Benefits

Available in material meeting Cooling Technology Institute (CTI) Standard 136

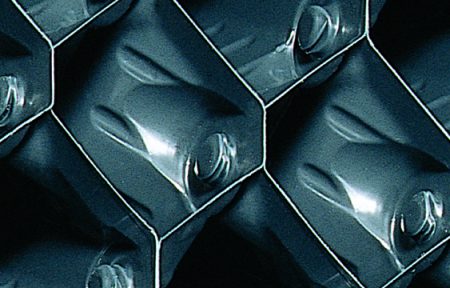

Available with AccuShield technology

Available with Mechanical Assembly technology

Learn More About Fill Products