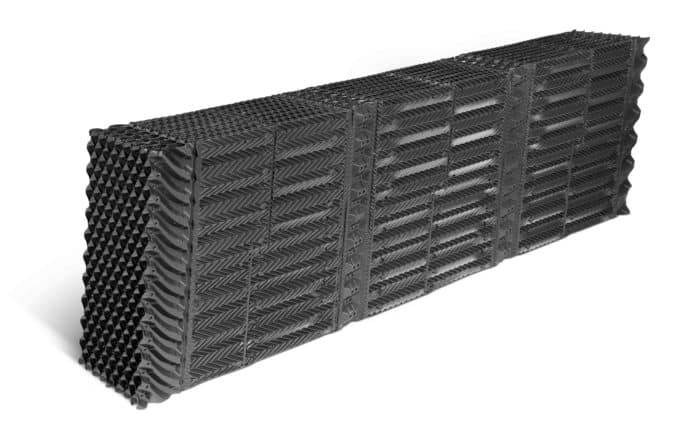

XF75Pro Overview

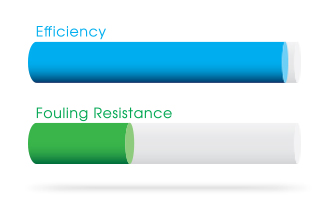

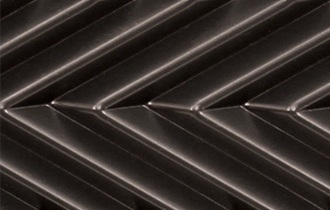

XF75Pro Crossflow fill improves air and water management over first-generation crossflow film fills, enhancing thermal performance by up to 10%. A new flute structure reduces pressure drop to improve thermal capability, and the enhanced structural design provides increased vertical pack strength, allowing for optimum product weight-to-height ratios. Herringbone fills with integrated inlet louvers (XF75Pro IL) and drift eliminators (XF75Pro ID) complete this efficient, high-performance, crossflow media system.

Benefits

Enhanced structural design for stronger packs.

Redesigned drift eliminator reduces drift rate.

Modified honeycomb feature reduces water splashout.

Learn More About Fill Products