Overview

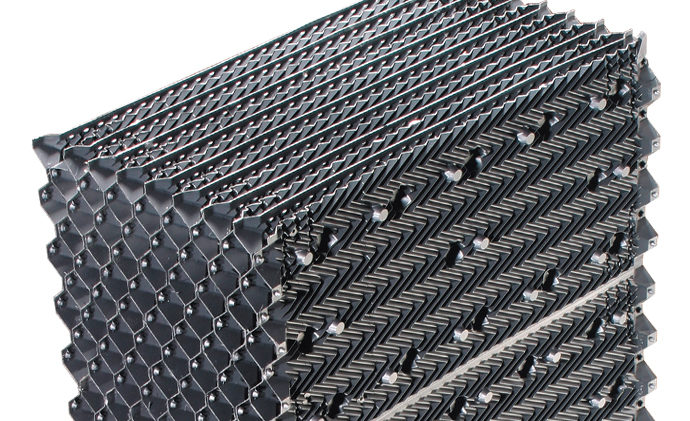

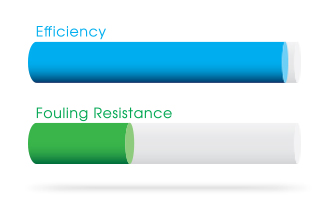

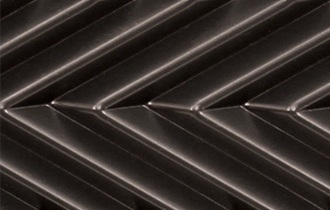

Herringbone fills take advantage of an engineered surface design to distribute water evenly over the entire fill area for high thermal performance. These fills are designed to replace OEM hanging fill sheets in crossflow cooling towers serving HVAC, light industrial, and other process cooling requirements.

Brentwood has invested heavily in research, development and testing of all cooling tower fill and drift eliminator products over the years. We have collected results from thousands of high-performing installations. Whether your needs are for counterflow or crossflow tower applications, we can provide expert, data-driven recommendations for the correct fill replacement to meet existing design criteria or improve upon older tower installations.

Benefits

Engineered herringbone surface for even water distribution

Bottom-supported by Brentwood’s XF Support System

Available in material meeting Cooling Technology Institute (CTI) Standard 136

Learn More About Fill Products