Overview

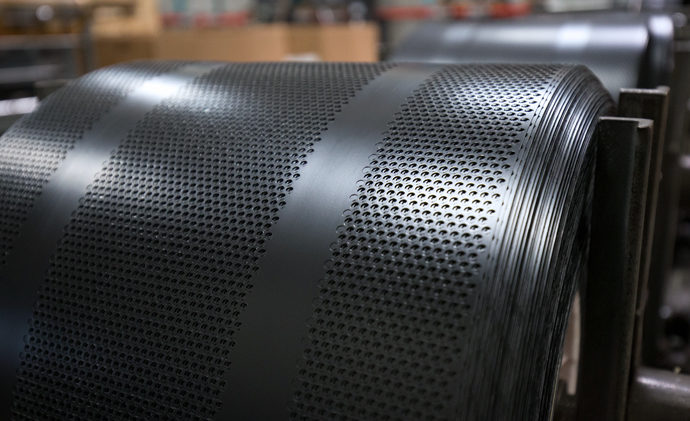

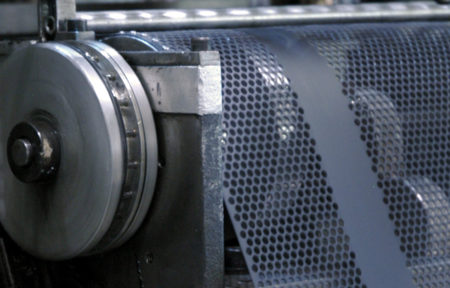

Brentwood is a leading supplier of Koroseal, also known as perforated plate wrap or battery perf, a material used to prolong battery life by preventing corrosion of the internal lead plates. We have been manufacturing this specially formulated PVC material for nearly 40 years, since the design and installation of our first custom press machine in the 1970s.

Today, we operate a vertically integrated, closed-loop system. High-precision material blending and in-house tooling give us full control to produce top-quality Koroseal while providing design flexibility to meet your specifications.

Product Details

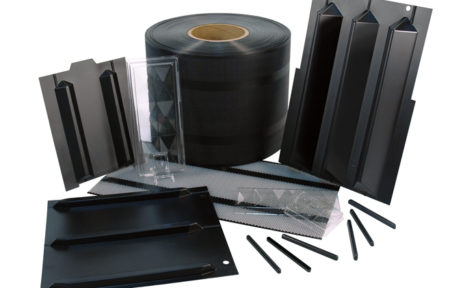

Available in standard roll stock & pre-cut sizes

Customizable perf patterns & border thicknesses

Able to be heat-welded & sealed onto the plate

Learn More About Koroseal