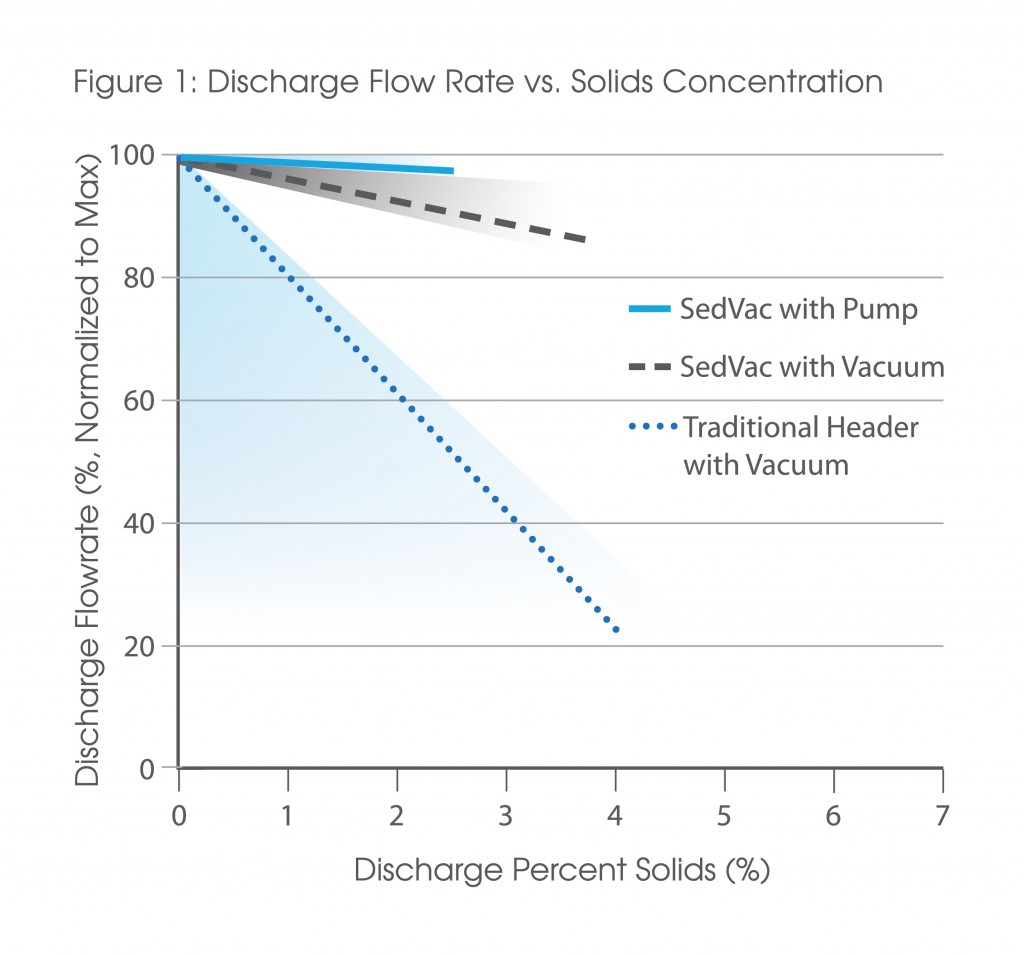

We often are asked about SedVac’s discharge flow rate during the course of working with consultants and operators on the sludge removal equipment selection for water treatment plants. SedVac’s flow rate is typically between 200-300 gpm when the sludge valve is opened. The total for the entire day would be calculated by the number of run cycles per day x run time per cycle (with valve open) x the sludge wasted rate.

Now, when this question comes up, it always presents an opportunity to segue into some performance comments about SedVac vs. some of the other types of equipment being evaluated. In general, this question is raised because the asker is either a.) looking to compare our discharge flow rate to another vacuum system or b.) considering the overall treatment process and how much water is being removed vs. how much sludge is being removed. We usually see traditional vacuum systems with flow rates less than 200 gpm. This is typical of the tube-shaped header design that utilizes tiny orifices to remove solids. These tube-shaped header suppliers may even tout the lower flow rate as a savings to the plant; however, this is common miss-information. We have found that tube shaped headers have to be run bi-directionally to clean what SedVac will clean in one forward pass, and even then the tube-shaped headers leave a compressed layer of sediment behind. SedVac is designed to remove more sludge and less water in half the time of other vacuum systems out there.

Figure 1 is pulled from our Sedvac Design Guide – check it out if you’d like to read more about our pilot studies. You can find this design guide and other technical content in myBrentwood.