That’s a good, and common, question. To answer it, we can run an example calculation, making a few assumptions:

That’s a good, and common, question. To answer it, we can run an example calculation, making a few assumptions:

- We will design our analysis around a counterflow, induced draft cooling tower utilizing blade-style eliminators.

- We will assume the water quality is sourced from a municipal supply that has a standard surface tension.

- We will assume that the average and peak velocities are within a drift eliminator’s operating range (i.e., the tower was designed to account for this).

- We will assume the droplet sizes and droplet volume are consistent throughout the entire operating time frame.

- And for simplicity, we will assume the tower operates fully for 8 hours per day, 7 days a week, for 50 weeks per year (or 2,800 hours per year).

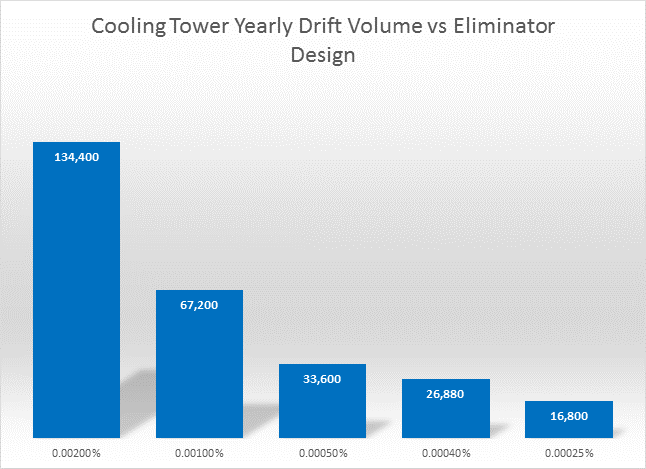

Example: A 4-cell counterflow cooling tower designed to cool 40,000gpm from 95°F to 85°F at 78°F WB (wet bulb temperature). The existing drift eliminators are blade-style and reduce leaving drift rate to 0.002% of the circulating water flow. Therefore, 40,000 * 0.002% = 0.80gpm. That’s 48.0 gallons per hour * 2,800 hours per year = 134,400 gallons per year.

The next-level drift eliminator upgrade would be to the basic cellular style, reducing leaving drift rate to 0.001% of the circulating water flow. Thereforhttps://www.brentwoodindustries.com/cooling-tower/counterflow-cellular-drift-eliminators/?model_type=3884e, 40,000 * 0.001% = 0.40gpm. That’s 24.0 gallons per hour * 2,800 hours per year = 67,200 gallons per year.

But the best upgrade would be to an enhanced cellular style, reducing leaving drift rate to as low as 0.00025% of the circulating water flow. Therefore, 40,000 * 0.00025% = 0.10gpm. That’s 6.0 gallons per hour * 2,800 hours per year = 16,800 gallons per year.

So, if the owner of this tower were to upgrade his drift eliminators to the most enhanced, current technology, he could reduce drift loss by 117,600 gallons per year. That’s more than the water needed to fill 8 standard backyard swimming pools in the U.S.! And it’s not only the cost of the water that can be saved but the cost of: the water treatment chemicals that are dispelled along with the water droplets, the impact of corrosion on any metal around the tower, and the potential environmental and health-related impacts of allowing that much circulating water to dispel from the tower.

All in all, a drift eliminator upgrade could yield a very quick return on investment.